Retrofitting Waste Systems in an Occupied Landmark Tower

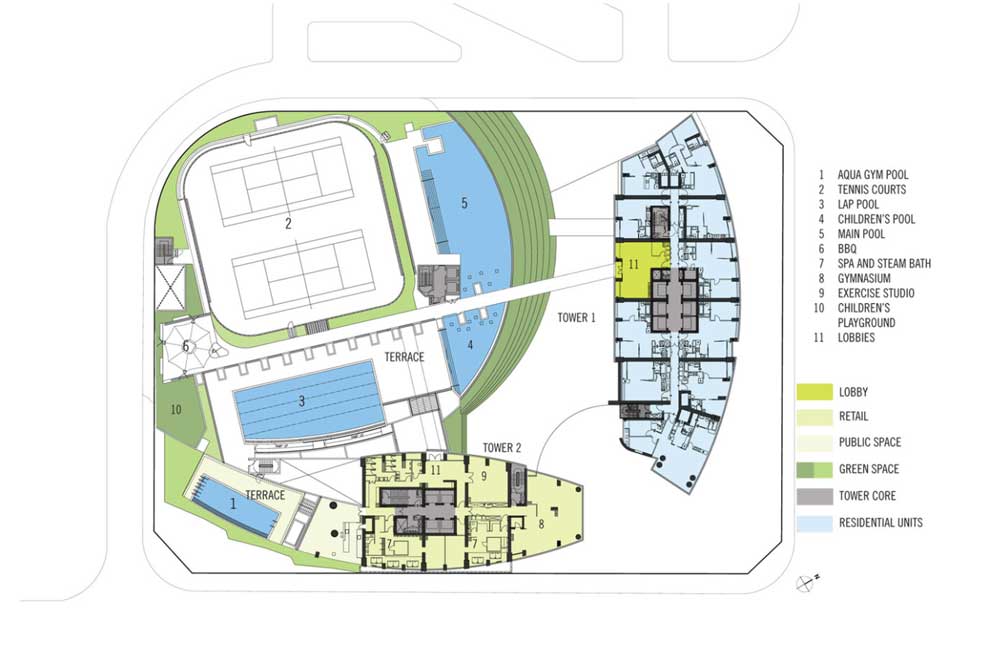

The Sail @ Marina Bay is a landmark 6-star waterfront condominium in Singapore’s Marina Bay district. Comprising two towers of 69 and 63 storeys with a total of 1,111 luxury residential units.

This retrofit project addressed the estate’s aging refuse disposal infrastructure by replacing and upgrading the general waste and recyclables chute systems in both towers. All work was carried out while the building remained fully occupied, posing significant challenges in logistics and noise controls on a daily basis.

Implementation Approach

The retrofit solution involved demolishing the original cellulose-fiber refuse chutes and installing new SS316 stainless steel chute pipelines in their place. The new chute system was engineered as a modular design and joined via movable collar couplings.

To mitigate noise and vibration in the 60+ storey chutes, each new chute section was wrapped with acoustic damping material, and all bracket supports were fitted with vibration-isolating pads, to reduce the sound of falling waste and prevent structural vibration transmission

A bottom-up demolition method was used to clear lower floors first, enabling concurrent installation of new chute segments while demolition continued above. Each floor was isolated to manage dust, noise, and resident safety.

Modular SS316 chute sections were installed floor by floor, acoustically damped, and vibration-isolated, ensuring compliance with stringent MCST noise and vibration standards

“Executing a 60-storey chute replacement in live conditions required precision engineering. The bottom-up method and acoustic isolation ensured the upgrade was seamless and compliant.”

In summary

Highlights

In summary

Highlights

Expertise in complex PWCS Projects

The Sail @ Marina Bay chute retrofit showcased GWS’s ability to deliver highly complex engineering projects in occupied high-rise environments. The new SS316 modular chute system improved maintainability, reduced noise and vibration, and enhanced waste handling efficiency.

Completed ahead of schedule, the project secured operational reliability while preserving the premium living standards in a Singaporean landmark residence.